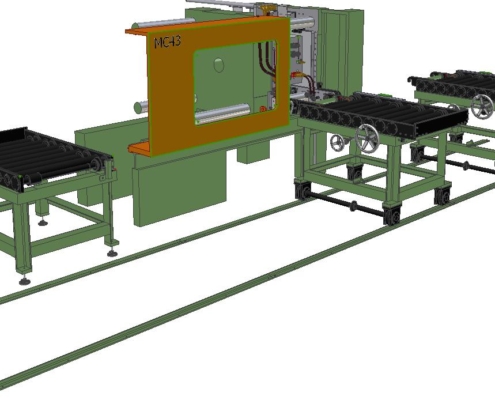

Quick change system for molds

SMO has been commissioned by Esselte from Sint-Niklaas to develop a quick change system for molds.

Operation:

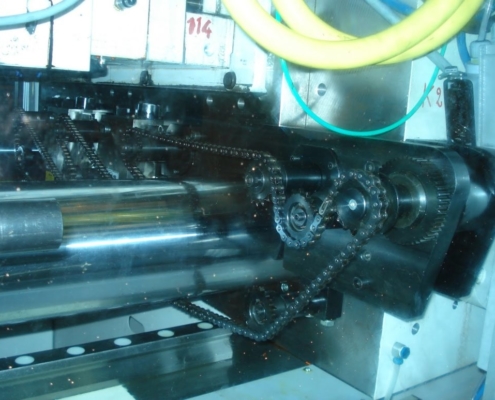

The mold is rolled on a cart, which is positioned on rails, and goes up to the injection molding installation. By manually operated rollers, the mold is positioned laterally in the injection molding machine and hydraulically clamped.

This system can be used for molds up to 7 tons.

Benefit:

A change of molds now takes between 15 and 30 minutes, whereas in the old system this could take 4 to 8 hours.

Subsequently, SMO has also developed other applications for the same system. These other applications are a transport cart with clamping system for the maintenance of the molds in the tool shop.

Want to know more? Contact SMO for more details and prices.